Washing and Winding

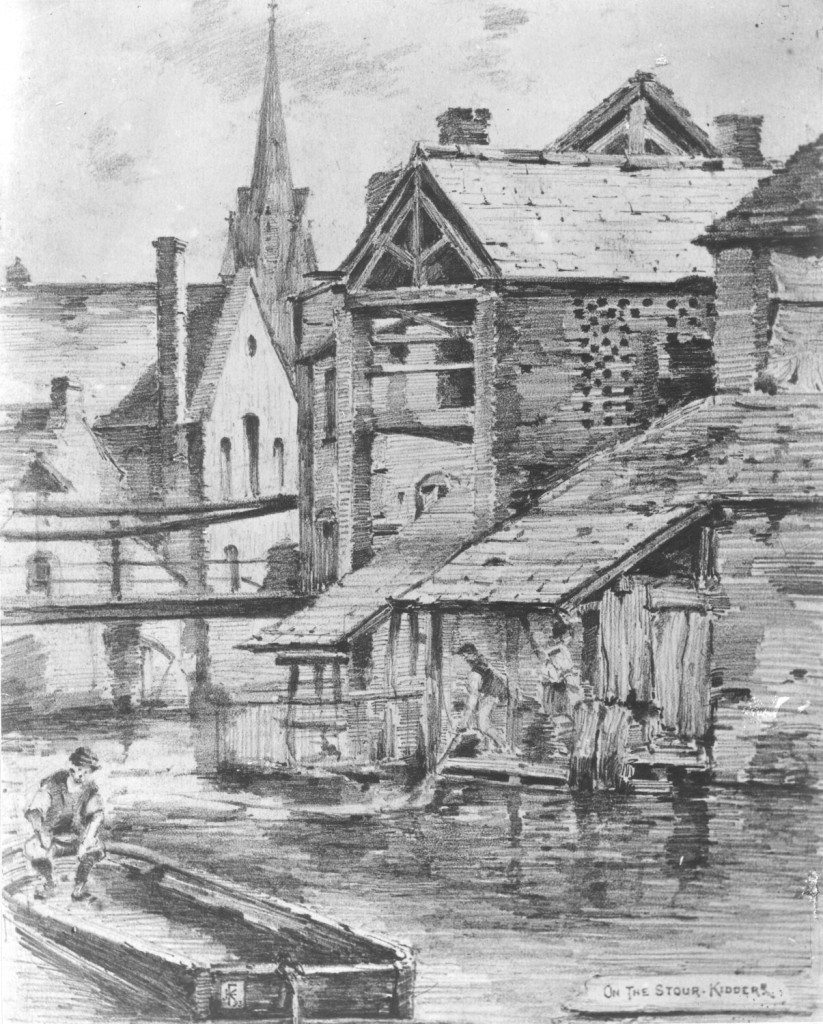

Image: Carpet Dyehousemen washing skeins of woollen yarn after dyeing in the water of the River Stour, Kidderminster. J Knox Ferguson, <i>Old Kidderminster</i> (n.d.).

Image from: Bewdley Museum

Each of the larger factories had its own warehouse and dye-house, often with direct access to the river Stour for washing the dyed yarn. The process was potentially hazardous for the dyehousemen. One observer watched them “standing on little platforms over the river balancing gaily coloured skeins of yarn in the water on long poles to cleanse them loose from dye with the skill of acrobats”. The yarn was then dried and wound onto bobbins by female bobbin winders, before being collected by the independent weavers.

« Previous in this sectionNext in this section »Continue browsing this section

Made in Kidderminster: the History of the Carpet Industry

Made in Kidderminster: the History of the Carpet Industry

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

Handloom Weaving

Handloom Weaving

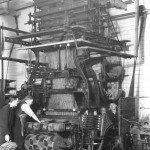

The Factory System

The Factory System

Washing and Winding

Washing and Winding

Washing and Winding

Washing and Winding

Technological Changes: the Scotch Loom

Technological Changes: the Scotch Loom

Technological Changes: the Brussels Loom

Technological Changes: the Brussels Loom

Technological Changes: the Jacquard Loom

Technological Changes: the Jacquard Loom

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

Working Conditions in Kidderminster Carpet Factories

Working Conditions in Kidderminster Carpet Factories

The Great Strike of 1828

The Great Strike of 1828

The Aftermath of the Great Strike of 1828

The Aftermath of the Great Strike of 1828

Kidderminster in the mid 19th Century

Kidderminster in the mid 19th Century

Kidderminster: the Factory Town

Kidderminster: the Factory Town