The Factory System

Image: Remains of Kidderminster’s first carpet factory at Mount Skipet.

Image from: Bewdley Museum (photograph taken in 1981)

As carpets became larger and more ornate, it eventually became necessary for larger or more looms to be used, and it was no longer possible for them to be housed in individual weavers’ homes. Some carpet factories were sometimes converted from other textile factories. In 1832, the carpet firm of John Broom, a descendant of the first John Broom, went bankrupt. The auction catalogue of the sale of his effects demonstrates very clearly both the wide variety in sizes of loom-shops and the numerous types of loom used at this time. Looms were generally manually operated with the occasional aid of water power.

« Previous in this sectionNext in this section »Continue browsing this section

Made in Kidderminster: the History of the Carpet Industry

Made in Kidderminster: the History of the Carpet Industry

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

Handloom Weaving

Handloom Weaving

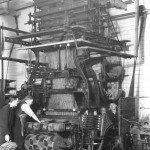

The Factory System

The Factory System

Washing and Winding

Washing and Winding

Washing and Winding

Washing and Winding

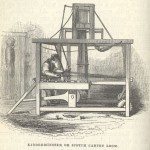

Technological Changes: the Scotch Loom

Technological Changes: the Scotch Loom

Technological Changes: the Brussels Loom

Technological Changes: the Brussels Loom

Technological Changes: the Jacquard Loom

Technological Changes: the Jacquard Loom

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

Working Conditions in Kidderminster Carpet Factories

Working Conditions in Kidderminster Carpet Factories

The Great Strike of 1828

The Great Strike of 1828

The Aftermath of the Great Strike of 1828

The Aftermath of the Great Strike of 1828

Kidderminster in the mid 19th Century

Kidderminster in the mid 19th Century

Kidderminster: the Factory Town

Kidderminster: the Factory Town