Washing and Winding

Image: River Stour, Kidderminster. Remains of brackets for a platform which was used by dyehousemen to wash wool looking towards Green Street, Kidderminster.

Image from: Bewdley Museum (photograph by F Johnson, 1979)

Weavers were completely responsible for the whole weaving process from bobbin to completed carpet, with the help of their half-weaver apprentices and draw-boys or girls. The completed carpet was always delivered to the factory counting house on set days of the week, known as Fall Days, which were usually Thursdays and Saturdays. The weavers, who were paid by the yard, were always males who had served their apprenticeships and often fiercely independent. In turn they were responsible for paying the workers under them and their own fuel and lighting. Although the factory owners usually owned the actual looms, it seems that the weavers did not have to pay any rental for these.

« Previous in this sectionNext in this section »Continue browsing this section

Made in Kidderminster: the History of the Carpet Industry

Made in Kidderminster: the History of the Carpet Industry

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

The Origins of Carpet Making in Kidderminster

Handloom Weaving

Handloom Weaving

The Factory System

The Factory System

Washing and Winding

Washing and Winding

Washing and Winding

Washing and Winding

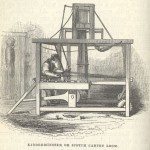

Technological Changes: the Scotch Loom

Technological Changes: the Scotch Loom

Technological Changes: the Brussels Loom

Technological Changes: the Brussels Loom

Technological Changes: the Jacquard Loom

Technological Changes: the Jacquard Loom

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

The Kidderminster Carpet Industry and the Wider World

Working Conditions in Kidderminster Carpet Factories

Working Conditions in Kidderminster Carpet Factories

The Great Strike of 1828

The Great Strike of 1828

The Aftermath of the Great Strike of 1828

The Aftermath of the Great Strike of 1828

Kidderminster in the mid 19th Century

Kidderminster in the mid 19th Century

Kidderminster: the Factory Town

Kidderminster: the Factory Town