Work and Labour

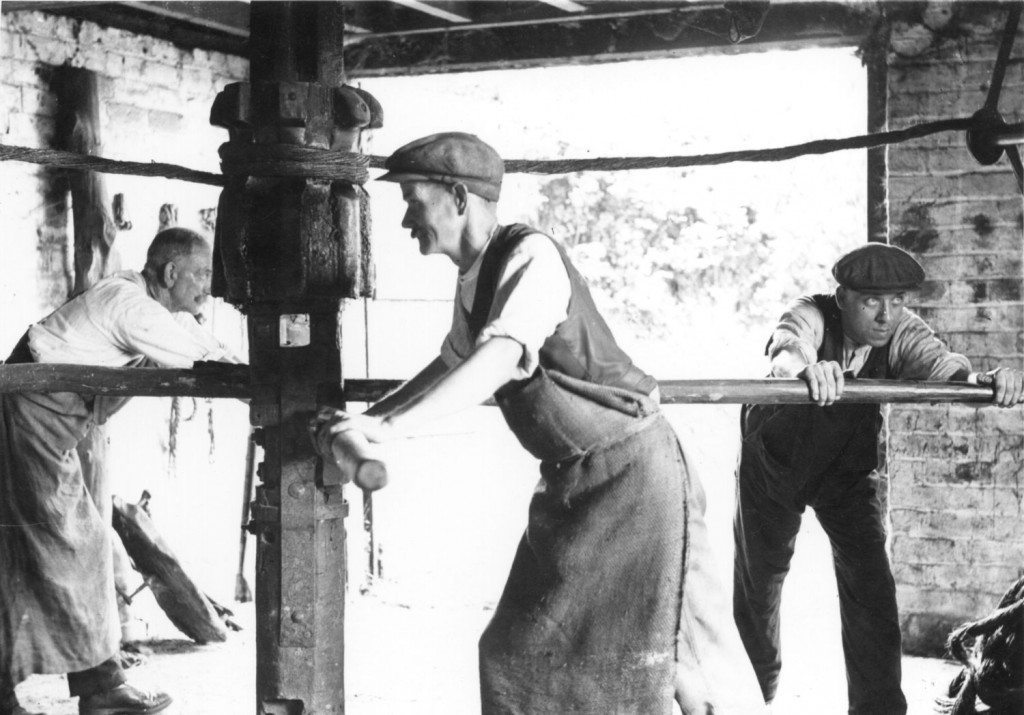

Image: Three men at Lowe’s ropeworks, Bewdley in about 1900 turning a capstan to wind rope.

[Image from: Bewdley Museum]

Men and women were employed on a variety of tasks, for instance rope spinning, rope finishing, twine finishing and labouring. Boys cleaned the raw hemp and cranked the “twisters” when yarn was spun into twine. Hours were long, up to 60 hours a week were common, and, as rope making was conducted in the open air, wet or freezing weather could make work difficult, unpleasant or impossible. The flooding of the river, a common event at Bewdley, could halt production, damage products and lead to the laying off of employees. Industrial injuries were possible. The firm’s records are not complete enough to provide evidence for early 19th century accidents, but later sources reveal show that equipment and machines could damage nails and fingers, hair could be caught in belting and workers could injure themselves slipping in icy conditions.

« Previous in this sectionNext in this section »Continue browsing this section

Rope Making

Rope Making

Rope Making and Bewdley

Rope Making and Bewdley

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Work and Labour

Work and Labour

Work and Labour

Work and Labour

Products and Markets

Products and Markets

Products and Markets

Products and Markets

Rope Making: Dressing or Hackling

Rope Making: Dressing or Hackling

Rope Making: Spinning

Rope Making: Spinning

Rope Making: Laying the Rope

Rope Making: Laying the Rope

Rope Making: Inserting the Tops

Rope Making: Inserting the Tops

Rope Making: Stretching

Rope Making: Stretching

Rope: Making: Mechanisation

Rope: Making: Mechanisation

The Decline of Rope Making

The Decline of Rope Making