Rope Making: Laying the Rope

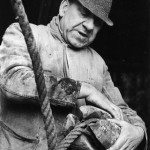

Image: The photograph shows a boy at Lowe’s ropeworks, Bewdley in about 1900 with the “jack” or “twister” which is set up for rope making. Boys were employed to crank the jack to turn yarn into rope. A large wooden “top”, which was used to separate the strands of yarn, is lying on the ground.

[Image from: Bewdley Museum]

Rope was made by twisting yarns together. Two pieces of machinery were required to “lay” the rope. These were the “twister” or “jack” and the “traveller” or “wain”.

- • The roper began by stringing yarn between the three hooks of the twister and one hook on the traveller.

- • When the twister was cranked the hooks revolved to form three stands.

- • The three strands were then twisted together by simultaneously cranking the twister and traveller in opposite directions.

- • The ropemaker’s assistant turned the crank handle of the jack and the hooks revolved at great speed. Each group of yarns twisted into a strand as the assistant turned the handle.

- • Soon the strands began to shrink because of the twist, pulling on the traveller. The roper pushed the traveller along the ropewalk. When the strands contracted to about a quarter of the length of the walk they were as highly twisted as it is possible without kinking. The rope was created.

Continue browsing this section

Rope Making

Rope Making

Rope Making and Bewdley

Rope Making and Bewdley

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Lowe’s Rope and Twine Manufactory

Work and Labour

Work and Labour

Work and Labour

Work and Labour

Products and Markets

Products and Markets

Products and Markets

Products and Markets

Rope Making: Dressing or Hackling

Rope Making: Dressing or Hackling

Rope Making: Spinning

Rope Making: Spinning

Rope Making: Laying the Rope

Rope Making: Laying the Rope

Rope Making: Inserting the Tops

Rope Making: Inserting the Tops

Rope Making: Stretching

Rope Making: Stretching

Rope: Making: Mechanisation

Rope: Making: Mechanisation

The Decline of Rope Making

The Decline of Rope Making