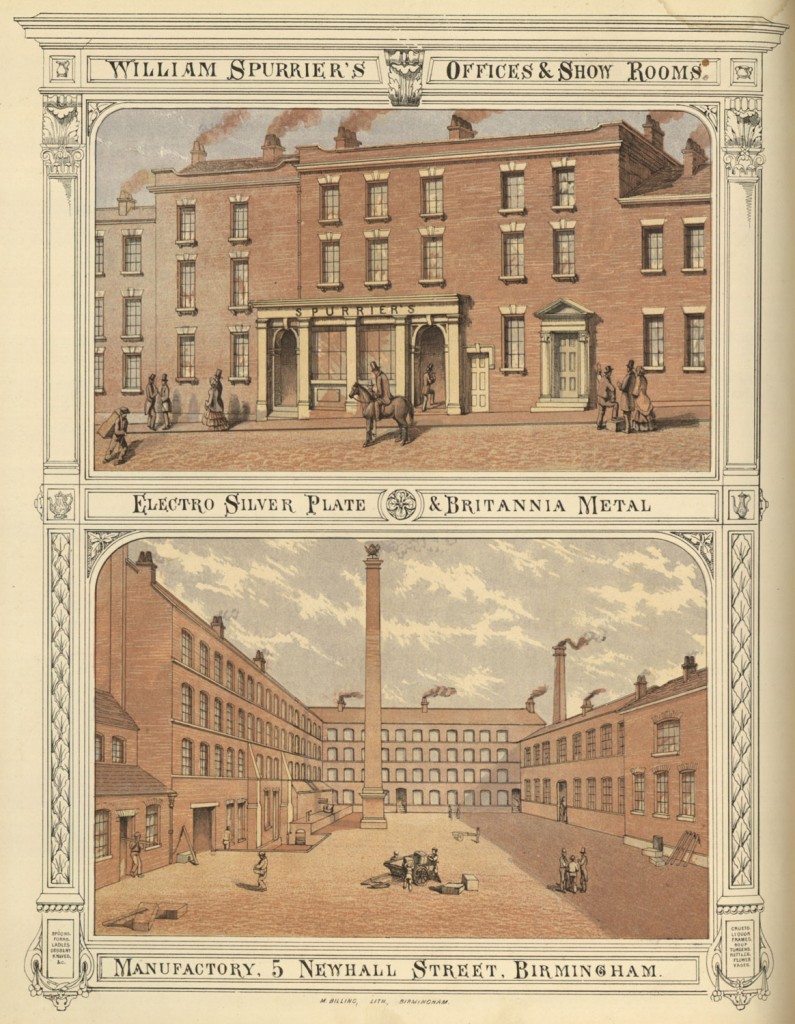

William Spurrier, Electro Silver Plate Manufacturer, Birmingham

Image: William Spurrier, Electro Silver Plate Manufacturer, Birmingham

Image from: The New Illustrated Directory Entitled Men and Things of Modern England, 1858

ELECTRO-PLATING

It may be well here to explain that no substances except the metals and charcoal are real conductors of electricity and that all other substances can conduct electricity only by suffering decomposition, the amount of electricity passing and the amount of decomposition effected preserving a constant ratio to one another. In all such cases of decomposition, the elements of the decomposing substance travel in opposite directions; one presenting itself at one of the poles or electrodes of the battery and the other element at the other pole or electrode. In the experiment we are describing, the teapot constitutes one pole or electrode of the battery and the silver plate constitutes the other. The electricity, in passing across the solution from the silver plate to the teapot, effects the decomposition of the silver salt, one of the elements, viz., the silver, yielding itself up at the teapot and the other element – the cyanogens – at the other electrode or silver plate. The silver accumulating on the teapot constitutes the plating and the cyanogens which presents itself at the silver plate, forms therewith a compound precisely similar in composition and equal in quantity to that which has been decomposed. The solution in the vat is thus kept uniform strength, the silver plate dissolving away at precisely the same rate as that at which silver accumulates on the article being plated. In short, looking at the process in its simplest aspect, we find that the effect of the arrangement we have described, is to transfer a quantity of silver from the suspended silver plate to the teapot. Having described the general principles of electro-plating, we may add that the articles to be plated are made up by the ordinary methods of working metals; that is to say, some patterns are stamped or raised in dies, others spun or raised in a lathe and others formed by casting. The several parts are connected together by soldering and the completed article is entirely coated with the film of silver by the process we have described. The manufacture of electro-plated wares is almost wholly confined to the plating of articles made of the alloy called German silver; that is an alloy of nickel, copper and zinc. This alloy is hard and white and is altogether better fitted for the manufacture of articles to be electro-plated than any other known metal or alloy.