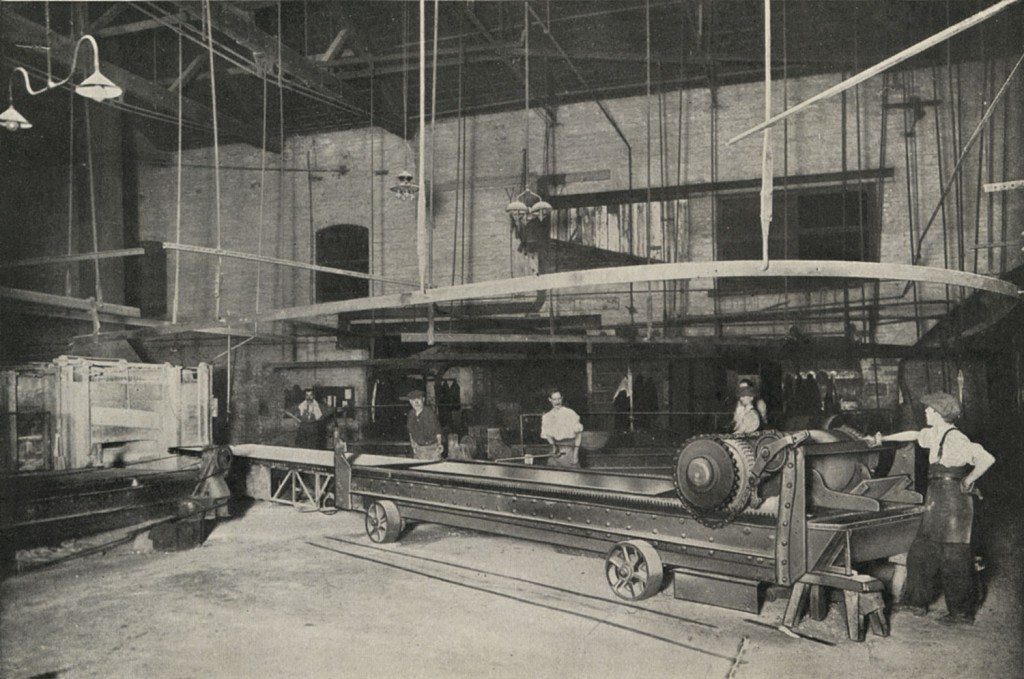

Plate or Sheet Glass

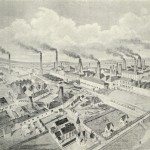

Image: Manufacture of Rolled Plate Glass. Chance Brothers & Co., Limited, 100 Years of British Glass Making 1824-1924 (Smethwick and Glasgow, Chance Brothers & Co., 1924).

Image from: Local Studies and History, Birmingham Central Library

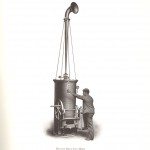

Blowing the “metal” into the form of a cylinder was the first stage of making sheet glass. J F Chance detailed the modes of production in his book. The workman judged the dimensions and thickness of the walls of these cylinders with a skill that could only be acquired after years of practice. The perfectly formed cylinder was then cut longitudinally and reheated in a flattening kiln or “lear” where it gradually opened out into a flat sheet, limited in size and thickness only by the weight of the glass that the blower could wield. The advantage over crown glass was that greater dimensions could be achieved in one single pane of glass, therefore, avoiding wastage. The disadvantage of this glass was an unevenness of surface and a comparative lack of brilliance. These shortcomings were soon resolved by the invention of grinding and polishing machines by James Timmins Chance.

« Previous in this sectionNext in this section »Continue browsing this section

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

Chance Brothers and Company

Chance Brothers and Company

The Arrival of Expert Workers

The Arrival of Expert Workers

The Chemical Works

The Chemical Works

Types of Glass

Types of Glass

Crown Glass

Crown Glass

Plate or Sheet Glass

Plate or Sheet Glass

Flint Glass

Flint Glass

New Technology

New Technology

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Company Philanthropic Activity

Company Philanthropic Activity

Relations between Workers and the Company

Relations between Workers and the Company

French and Belgian Workers

French and Belgian Workers

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks