The late 18th Century: John Ingram and Charles Hunt

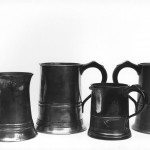

Image: From left to right, a glass-bottomed quart tankard, half-pint beaker and pint tankard made by Ingram and Hunt, Bewdley pewterers in the late 18th century. Glass-bottomed tankards were introduced for various reasons. One common story is that they would enable carousing tavern drinkers to see the King’s shilling when it was dropped into their ale, they could then avoid being press-ganged into the Royal Navy, if they were not too inebriated. Another explanation is that they were an imaginative response by pewter manufacturers when faced by competition from glassmakers. Glass tankards enabled a customer to assess the clarity of his beer. A glass bottom to a pewter vessel served the same purpose. This is more evidence of the ability of the local industry to adapt to market forces.

[Image from: Bewdley Museum]

At some time before 1778, presumably to acquire additional capital, John Ingram junior entered a partnership with Charles Hunt, his brother-in-law. Account books for the business survive and record the names of over seven hundred customers throughout England and Wales between 1769 and 1790. Pewter goods were also exported to North America. The firm produced, or bought for resale, tea pots, urinals, candlesticks, ink stands, tooth powder boxes, ear syringes and inkpots as well as dozens of other items. One hundred thousand spoons and thousands of tankards and tavern pots were manufactured annually. Labour shortages seem to have been a problem. In 1783, Ingram and Hunt advertised in Aris’s Birmingham Gazette for two men to work at their spoon works in Bewdley.

By this time Ingram and Hunt were providing a stimulus for other local industries and commercial activities including glass for tankard bottoms, green baize for the underside of candlesticks and rope for packaging. The firm also purchased grease to lubricate the finishing wheels and serve as a flux in the soldering process. In 1805 – 1806, the firm bought 53 lbs of grease from nearby suppliers. As Bewdley was home to major cattle markets and tanneries, the raw material was at hand!

« Previous in this sectionNext in this section »Continue browsing this section

An Innovative Metal Industry: Pewter and Mass Production in Bewdley

An Innovative Metal Industry: Pewter and Mass Production in Bewdley

Bewdley’s Importance for the Pewter Industry

Bewdley’s Importance for the Pewter Industry

Using Pewter

Using Pewter

Making Pewter

Making Pewter

Local Origins

Local Origins

John Duncumb and Mass Production

John Duncumb and Mass Production

John Duncumb and Mass Production

John Duncumb and Mass Production

John Duncumb and Mass Production

John Duncumb and Mass Production

The mid 18th Century: Stynt Duncumb

The mid 18th Century: Stynt Duncumb

The late 18th Century: John Ingram

The late 18th Century: John Ingram

The late 18th Century: John Ingram and Charles Hunt

The late 18th Century: John Ingram and Charles Hunt

The late 18th Century: John Ingram and Charles Hunt

The late 18th Century: John Ingram and Charles Hunt

The early 19th Century: Crane and Stinton

The early 19th Century: Crane and Stinton

The early 19th Century: Joseph Morgan

The early 19th Century: Joseph Morgan

Decline

Decline